Sandwich panels have been gaining popularity in construction due to their durability, insulation, and lightweight. However, one question that often arises is whether sandwich panels are load-bearing. In this article, we will explore the characteristics of sandwich panels and determine whether they are suitable for supporting structural loads.

What are sandwich panels?

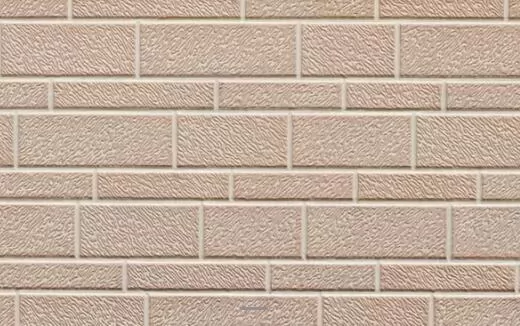

Sandwich panels consist of two thin outer layers, called skins, which are bonded to a thick, lightweight core. The outer layers can be made from a variety of materials, including metal, wood, concrete, or plastic, while the core is typically made from foam, honeycomb, or a combination of both. Sandwich panels are known for their excellent thermal and acoustic insulation properties and are commonly used in walls, roofs, and floors of buildings.

Load-bearing capacity of sandwich panels

Sandwich panels can be designed to have load-bearing properties. The load-bearing capacity of a sandwich panel depends on the properties of its skins, core, and bonding materials. The thickness and type of each layer can be adjusted to provide the required strength and stiffness for a specific application.

When designing a load-bearing sandwich panel, it is essential to consider the type and magnitude of the expected loads. For example, sandwich panels used in wall systems may need to resist wind and seismic loads, while roof panels may need to support snow loads. The panel thickness, skin material, and core density are critical factors that can affect the load-bearing capacity of a sandwich panel.

Advantages of using load-bearing sandwich panels

Load-bearing sandwich panels offer several advantages in construction. First, they are lightweight, which makes them easier to handle and transport. Second, they are easy to install, as they can be prefabricated in a factory and quickly assembled on-site. Third, they provide excellent thermal and acoustic insulation, which can lead to energy savings and a comfortable living environment. Fourth, they are cost-effective compared to traditional construction methods, as they require fewer materials and labor.

Limitations of using load-bearing sandwich panels

While load-bearing sandwich panels have many advantages, there are also some limitations to their use. One limitation is their susceptibility to moisture and water damage, which can compromise their strength and durability. Therefore, it is important to use appropriate sealants and protective coatings to prevent water infiltration. Additionally, the joints between the panels must be properly sealed to ensure airtightness and prevent air leakage, which can lead to energy loss.

Conclusion

In summary, sandwich panels can be designed to have load-bearing properties. Their load-bearing capacity depends on the properties of their skins, core, and bonding materials. Load-bearing sandwich panels offer several advantages in construction, including their lightweight, ease of installation, and thermal and acoustic insulation properties. However, they also have some limitations, such as their susceptibility to water damage and the need for proper sealing and joint treatment. It is important to consult with a structural engineer to determine the appropriate type and thickness of sandwich panel for a specific application.

We are a sandwich panel supplier. If you are interested in our products, please contact us now!