Introduction of sandwich panels

A sandwich panel is any structure made of three layers: a low-density core, and a thin skin-layer bonded to each side. Sandwich panels are used in applications where a combination of high structural rigidity and low weight is required.

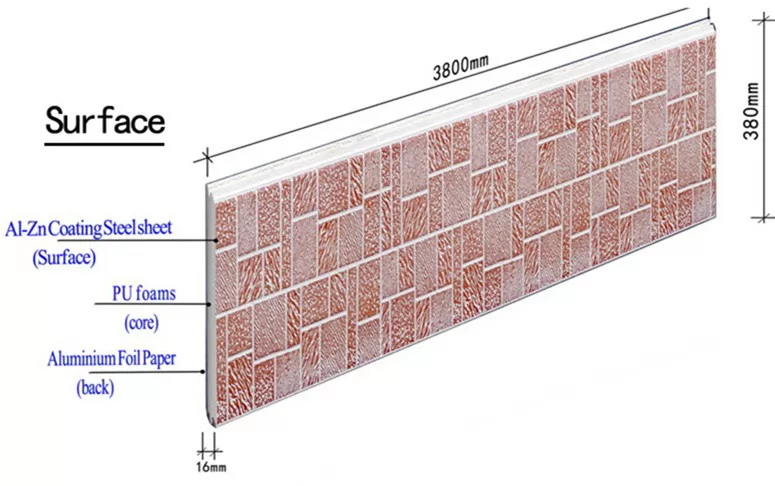

The pu sandwich panel consists of a panel of three different layers of material.

The first layer: Al-zn alloy coated steel plate

Second layer: PU foam

The third layer: aluminum foil paper

The sandwich panel is easy to install, lightweight and efficient. The filling system also uses a closed-cell molecular structure to prevent condensation of water vapor.

ts main use is in the large industrial construction industry. Such as cold storage, large stadiums, hospitals, old building renovations, schools, libraries, residential and so on.

Sandwich panel classification

Sandwich panel classification

According to the core material in the middle:

RW sandwich panel

PF sandwich panel

PU sandwich panel

XPS sandwich panel

Eps sandwich panel

Advantages of sandwich panels

Lightweight: Since most of the volume is a layer of foam, the density of the foam is very small. The weight of the entire sandwich panel is not as heavy as a panel of the same size.

Fire protection: This is a major feature of sandwich panels. Because most of its materials are non-combustible and difficult to burn materials, it can meet the requirements of house exterior wall fire protection.

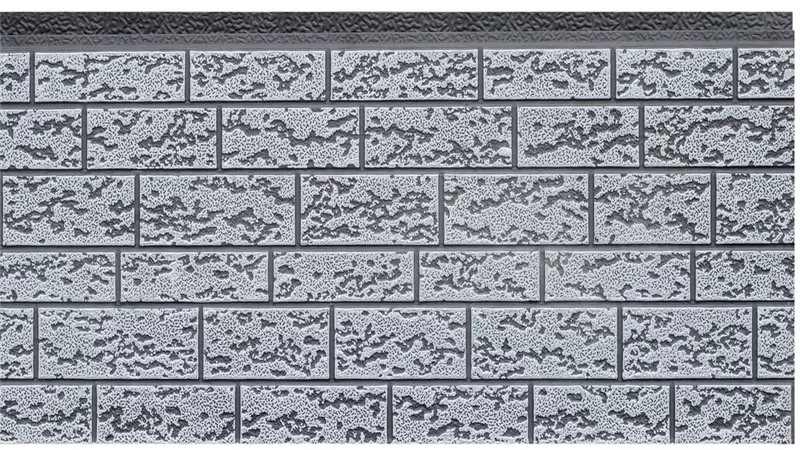

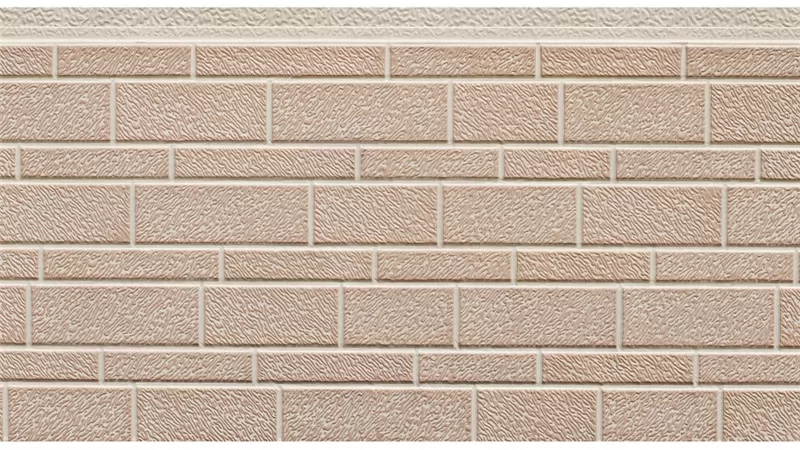

Customized appearance: The outer surface of the sandwich panel is customizable in pattern and color. This feature can be used with a variety of groups to decorate the exterior of the house.

Insulation performance: Commonly used core materials are RW, PF, PU, XPS, eps. The special properties of these materials can ensure the insulation performance of the building.

Anti-noise: The core board can prevent noise from reaching 40-60 decibels. Can provide a quiet environment.

Easy to install: The sandwich panel has a simple structure and lightweight, and is equipped with a chain interface. A worker can install about 50 square meters a day.

Sandwich panel installation steps

1. Install steel keel

2. Install the boot unit

3. Install the connecting parts

4. Mounting corner parts

5. Install widgets

6. Install the closing part

Pattern type of sandwich panel

Metal wall panel laminates have low cost, low maintenance costs, energy saving, long life and sustainability.

The sandwich panel is light in weight and stable in structure. It has a certain absorption energy and is able to withstand earthquakes.

Superior insulation performance, even up to 40 degrees outside. The indoor temperature is still comfortable and cool.

Superior fire resistance, wall panels are composed of non-flammable and flame retardant. Protect the safety of the family.

Read more about pu wallpanel content